Transform Your Cell Therapy Manufacturing With Non-Viral Gene Delivery

Fast, Scalable, and Cost-Effective Stable Gene Transfer Solution

TcBuster is a large capacity transposon system that enables transfer and stable integration of multiple genes of interest. An effective alternative to viral vectors, TcBuster offers significant time and cost savings during the development of cell therapies, such as CAR T or CAR NK.

TcBuster Reagents and Uses |

|||

| mRNA Transposase | TCB-001.1-100 (100 µg) | 100 tests at 1 µg each | - Useful for system evaluation |

| TCB-001.1-500 (500 µg) | 500 tests at 1 µg each | - Useful for further development | |

| TCB-001.1-GMP (500 µg) | 500 tests at 1 µg each | - GMP grade - Useful for pre-IND process development and ex vivo clinical applications |

|

| TcBuster-Compatible Transposons | TCBP001-100 (100 µg) | 25-100 tests at 1-4 µg each | - Multicistronic CAR-containing transposon - Useful in cell therapy applications as an experimental control |

| TCBP002-100 (100 µg) | 25-100 tests at 1-4 µg each | - Whole plasmid insertion of eGFP with no untransposed plasmid expression - Useful in bioprocessing system evaluation as an experimental control |

|

| Custom Transposons | Contact techsupport@bio-techne.com for more information | - For process development using your own therapeutic cargo - Utilizes partnership with Aldevron™ |

|

| Anti-TcBuster-M Transposase Antibody | MAB11511 (25 µg, 100 µg) | 1 µg/mL for Western Blot 20 µg/mL for Simple Western |

- Primary antibody detects TcBuster-M transposase enzyme in Western blotting applications |

How Does the TcBuster System Compare to Virus-Based Systems?

Gene transfer is a critical step in generating cell therapies and biologics. While viral vector-based engineering (e.g. lentivirus or AAV) has been the standard for delivering DNA cargo to cells, the TcBuster system provides an alternative, non-viral solution using standard electroporation methods. This system has several advantages over traditional viral options:

- Reduced time to market and cost requirements for cell therapies

- Increased cargo capacity, high editing efficiency, and delivery of multiple genes in single vector

- Stable expression of DNA cargo with a de-risked insertional profile

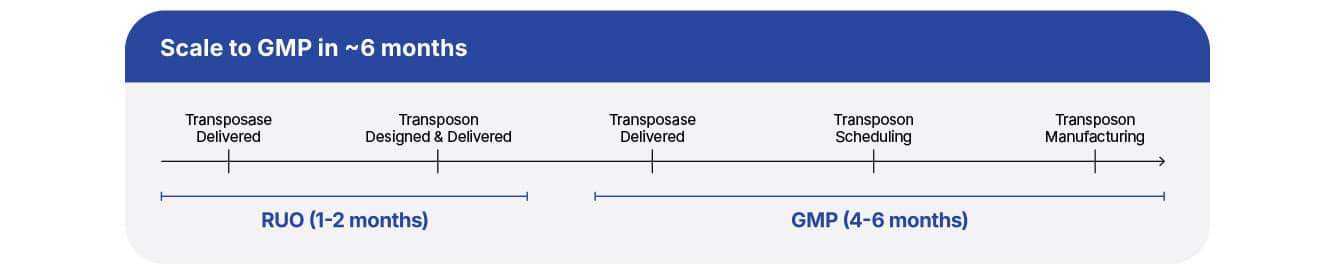

- Strong and reliable supply chain for both RUO & GMP grade material

- Scale effortlessly from research to clinical and commercial stages with reduced batch-to-batch variability and no need for viral preps

- Flexible and non-exclusive license options plus robust technical and regulatory support

A Story of Success: Luminary Therapeutics

Luminary Therapeutics is using the TcBuster system to manufacture their cell therapies, and their LMY-920 program has passed 3 INDs with TcBuster! At SITC 2024, Phase 1 results were reported for a BAFF CAR-T trial using TcBuster, demonstrating the first successful clinical use of the system.

"Moreover, the novel, clinical-stage TcBuster transposon system is utilized to improve manufacturing timelines, efficiency, cost, and safety."

How Can Bio-Techne Support You and Your Projects?

We are your partner in cell therapy - and we have solutions to your cell therapy roadblocks.

- Bio-Techne is here to stay, with over 40 years of scientific excellence

- We provide a strong supply chain, for both our research grade and GMP products

- We offer flexible licensing on our materials when you bring them the clinic or commercialization

- Regulatory support, with a DMF coming soon, and the ability to support worldwide customers with letters of authorization

- Robust technical service to support you while you evaluate the system

| TcBuster Resources | Scientific Articles and Presentations | ||

| Literature | Videos & Webinars | Papers | Posters & Abstracts |

| TcBuster v. Lentivirus App Note | Non-Viral Gene Delivery with TcBuster | Bridge et al. | Caimi et al. BAFF CAR-T Study |

| De-Risk Cell Therapy Manufacturing With TcBuster | Transposon Gene Editing Mechanism | Gurney et al. | TcBuster vs. Lentivirus in T Cells |

| Enhancing Cell Line Development App Note | Cell Therapy Development Webinar | Gurney et al. (2) | TcBuster-M System in T Cells |

| TcBuster-M + Nanoplasmid Vector System | CAR-T Manufacturing Webinar | Skeate et al. | |

| Custom DNA Transposons Guide | Wong et al. | ||

| Non-Viral Gene Engineering Whitepaper | |||

Partner with ScaleReady for TcBuster applications in immune cell therapy.

For other applications using TcBuster, contact a gene engineering expert with the form below.